Controls Optimization and RCx

Effective controls optimization and retro-commissioning depend on informed operators as much as technical execution. Rundell Engineering integrates sequence development, verification, and operator training to deliver durable performance.

Controls Optimization

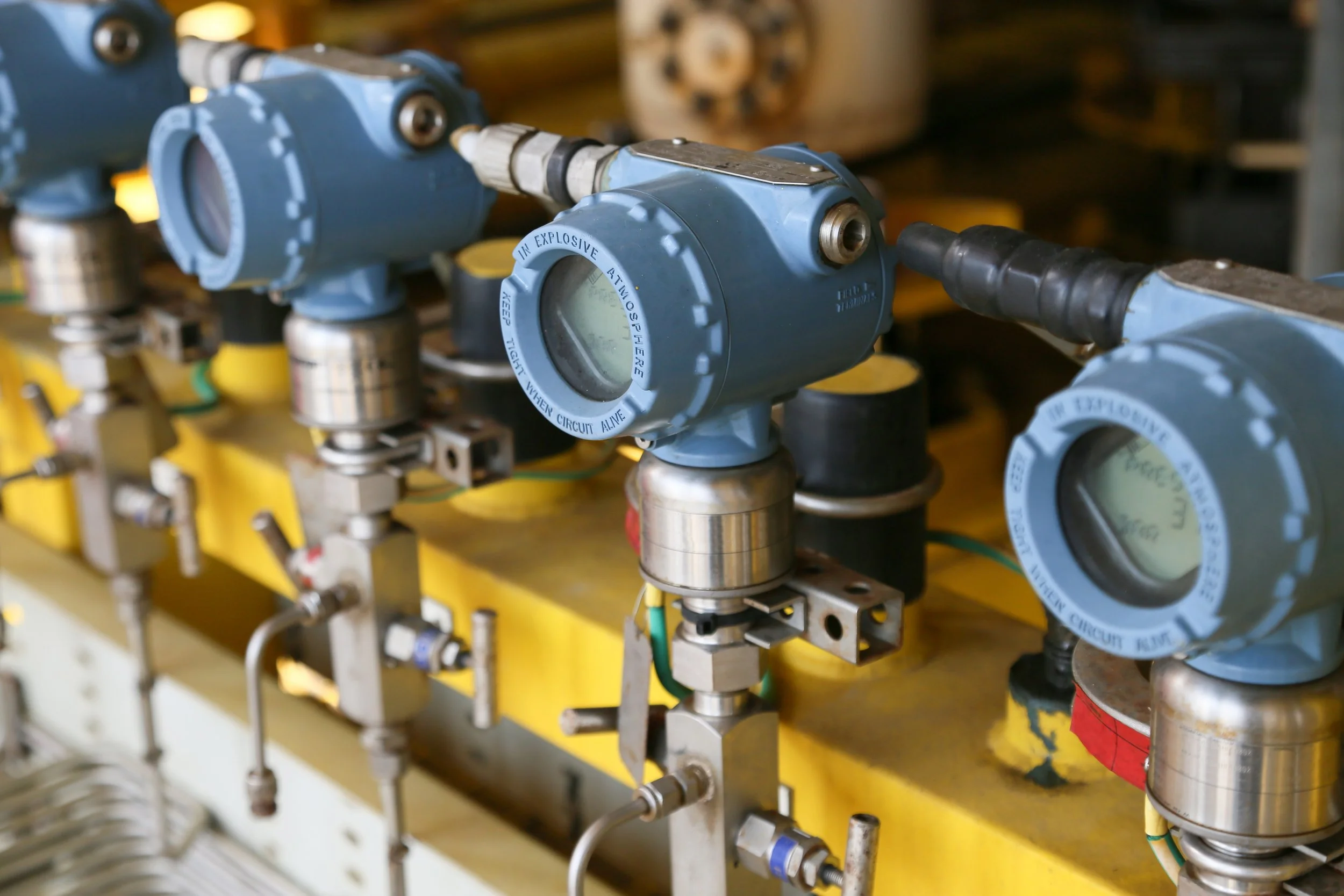

Controls optimization ensures that critical mechanical systems operate efficiently across their full range of real-world conditions. Many building automation systems rely on one-off or incomplete sequences that fail to take advantage of the equipment’s capabilities and are ultimately overridden when operators lose confidence in their performance.

Effective optimization balances system operating parameters to achieve stable, efficient operation at the system level. Knowing when and how to apply best-practice frameworks such as ASHRAE Guideline 36 requires a thorough understanding of system dynamics, operational constraints, and facility priorities. Rundell Engineering works with controls vendors to implement clear, proven sequences of operation, then commissions those sequences and verifies performance to ensure results persist.

Typical optimization focus areas include:

Chilled water plant optimization

Boiler plant and cogeneration optimization

HVAC system optimization

Laboratory ventilation optimization

Retro Commissioning (RCx)

Assets cannot be fully optimized when existing sensors and controlled hardware are not reliable and not trusted. A lack of trust in the sensor information and device operation leads to an eventual overriding of automation and sub-optimal performance. Retro commissioning, when paired with implementation of best-in-class sequence updates, is an effective combination to improve performance of existing systems. Rundell Engineering follows the NEBB Standard S120 process and holds all required certifications for NYC LL87 including ASHRAE BEAP and BCxP certifications..

Operator Training

The theory and the reality of operation are not the same. When theory is compared to the actual observed operation, important insights are gained. A key component to system optimization is ensuring everyone is on the same page with both the principles of operation and the system performance objectives. Even when systems are not being optimized, simply facilitating discussions between operators on different shifts with different perspectives of operation can be valuable. Building those discussions on a foundation of engineering fundamentals improves the quality and legitimacy of that discussion.